HOME > News

NEWS

2013-05-27

20130527 Safety Information

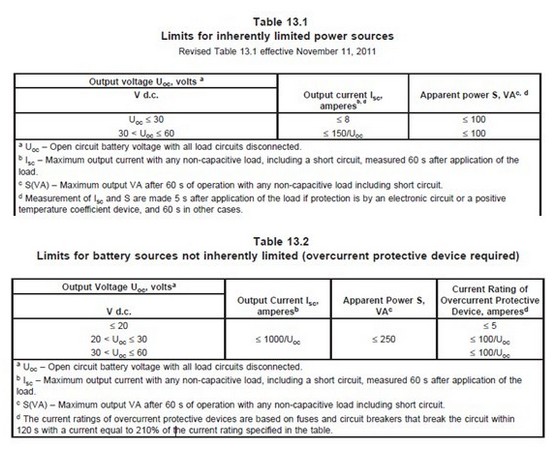

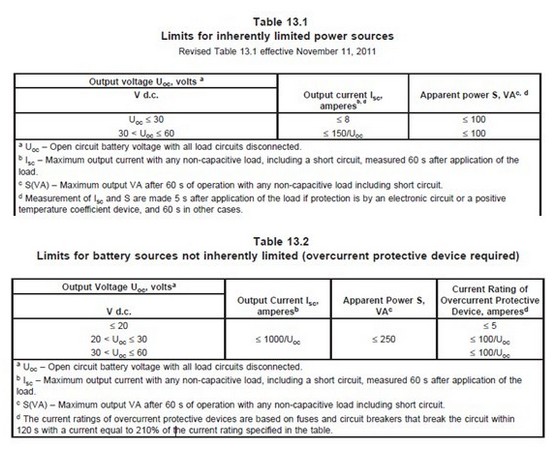

In IEC 60950-1 safety standard has required IT products must provide a suitable fire enclosure.

But also requires that when an IT product's power is limited power supply (Limited Power Source)

to power, if the electronic components are placed in fire rating V-1 above PCB, then the product can

not have to provide fire enclosure, but also is that you can use HB flame rating of shell material.

Therefore, manufacturers are required as power (including battery) comply with LPS requirements.

Battery products, typical test project with limited power LPS standards such as: UL2054 "Household

and Commercial Batteries", which applies to portable one (non-rechargeable) batteries and secondary

(rechargeable) batteries, these batteries can contain a single section, multi-section, series, parallel or

series-parallel multi-cell battery packs. There battery LPS in UL2054 test items specified in the standard

battery accord Limited Power Source trials before they can be marked on the battery label marked LPS.

The following example with UL2054 standard test method for battery LPS a brief introduction:

1 Test ambient temperature 20 ± 5 ° C.

2.6 After the battery is fully charged the corresponding single fault protection device (usually MOSFET).

3.3 batteries within 1 minute battery used to measure the maximum output current, three batteries within

1 minute battery used to measure the maximum output power.

4 current and power values shall not exceed the following requirements of Table 13.1 or 13.2.

5 Table 13.2 for a cell output current limiting fuse, the power situation.

6 Use 13.2 when, fuse's rating shall not exceed 5A, and the need to fuse the possibility of experimental

verification of 210% of its rated current fuse under two minutes.

In the actual test, many battery manufacturers in the design of the battery does not increase over current

or over-temperature protection device or do not take into account the special requirements of the following

two resulting LPS test failed.

Table 13.1 d) provides for the use of circuit protection device or a positive temperature coefficient

(e.g. PTC, etc.) require 5 seconds must be less than the maximum output current of 8.0 A; for other

protective devices, requires 60 seconds maximum output current must be less than 8.0 .

Table 13.2 d) over-current protection devices such as FUSE or breaker at 210% of rated current,

the required action within 120s.

Therefore battery manufacturers early in the design should take into account the standard

requirements for the special protection device, thus the choice of appropriate specifications FUSE

PTC or other protective devices, in order to avoid failure in the test.

But also requires that when an IT product's power is limited power supply (Limited Power Source)

to power, if the electronic components are placed in fire rating V-1 above PCB, then the product can

not have to provide fire enclosure, but also is that you can use HB flame rating of shell material.

Therefore, manufacturers are required as power (including battery) comply with LPS requirements.

Battery products, typical test project with limited power LPS standards such as: UL2054 "Household

and Commercial Batteries", which applies to portable one (non-rechargeable) batteries and secondary

(rechargeable) batteries, these batteries can contain a single section, multi-section, series, parallel or

series-parallel multi-cell battery packs. There battery LPS in UL2054 test items specified in the standard

battery accord Limited Power Source trials before they can be marked on the battery label marked LPS.

The following example with UL2054 standard test method for battery LPS a brief introduction:

1 Test ambient temperature 20 ± 5 ° C.

2.6 After the battery is fully charged the corresponding single fault protection device (usually MOSFET).

3.3 batteries within 1 minute battery used to measure the maximum output current, three batteries within

1 minute battery used to measure the maximum output power.

4 current and power values shall not exceed the following requirements of Table 13.1 or 13.2.

5 Table 13.2 for a cell output current limiting fuse, the power situation.

6 Use 13.2 when, fuse's rating shall not exceed 5A, and the need to fuse the possibility of experimental

verification of 210% of its rated current fuse under two minutes.

In the actual test, many battery manufacturers in the design of the battery does not increase over current

or over-temperature protection device or do not take into account the special requirements of the following

two resulting LPS test failed.

Table 13.1 d) provides for the use of circuit protection device or a positive temperature coefficient

(e.g. PTC, etc.) require 5 seconds must be less than the maximum output current of 8.0 A; for other

protective devices, requires 60 seconds maximum output current must be less than 8.0 .

Table 13.2 d) over-current protection devices such as FUSE or breaker at 210% of rated current,

the required action within 120s.

Therefore battery manufacturers early in the design should take into account the standard

requirements for the special protection device, thus the choice of appropriate specifications FUSE

PTC or other protective devices, in order to avoid failure in the test.

NEWS

NEWS